You can go straight to our waggonway maps by selecting the button below or go there after reading the story of the waggoneways

The Story of the Waggonways

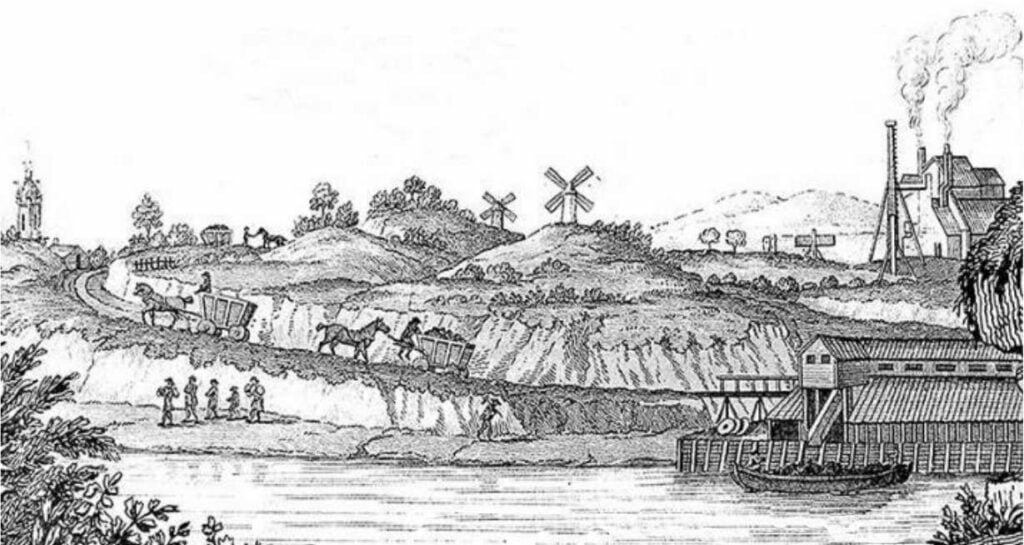

A Midlands entrepreneur, Huntingdon Beaumont with ambitions to break into the London market by transporting coal there from Warwickshire and Leicestershire, had built the Wollaton waggonway near Nottingham in 1603 -1604 which was about 2 miles long. The waggonway proved to be an extremely efficient method of transporting coal, but it appears not to have been a financial success. The pits it served were soon exhausted, the local market was flooded and the Trent was so tortuous that it was unable to carry the quantities of coal being produced.

Beaumont’s next venture was to attempt to compete with the trade on the Tyne by building waggonways in Northumberland at Bebside and Plessey in about 1606, exporting coal from Blyth to London, but this venture also proved unsuccessful. Sadly, he lost considerable sums of borrowed money and died in Nottingham Gaol in 1624, having been imprisoned for debt.

The Whickham Grand Lease Way, which operated between 1621 and an unknown date between 1706 and 1723, is believed to be the world’s first commercially successful railway. It is thought to have been built by a local landowner and engineer, Robert Surtees. It succeeded where others had failed, because the cost of constructing and operating it was shared by a consortium of coal owners. Moreover, the way gained popular acceptance by the local population which had suffered from the disruption and damage to roads and adjoining land, caused by the daily transport of coal hauled by several hundred carts (wains) each pulled by four animals.

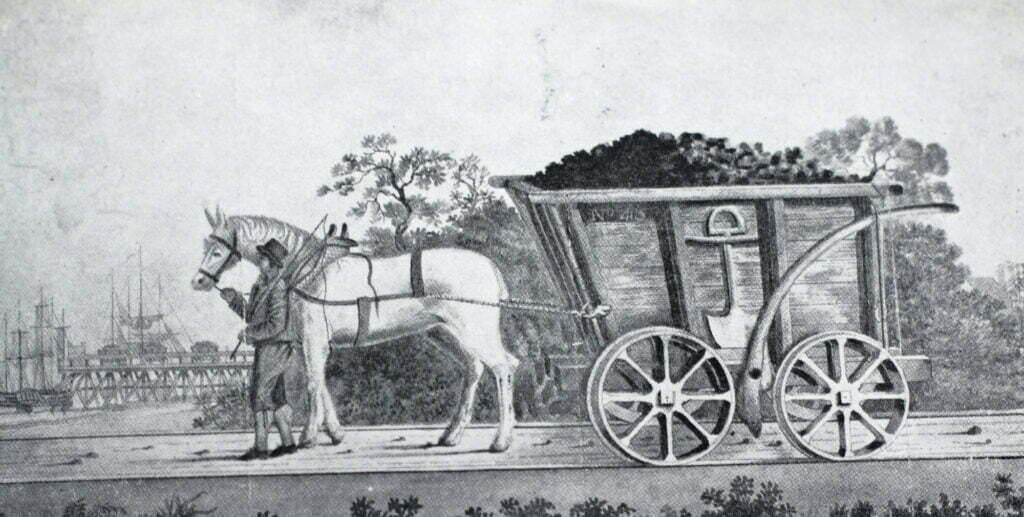

Waggonways were railways, initially using wooden rails, linking collieries with riverside wharves known as staiths. Coal would be carried on them in large waggons known as chaldrons. Each waggon would be under the control of one man with a horse. The horse would be used to pull the waggon on level stretches and uphill stretches. The gradients would be mitigated as much as possible by the use of cuttings and embankments (batteries) and streams would be crossed by either wooden trestles (or later by stone bridges) or by creating batteries across the valleys and culverting the stream through them.

A double track waggon way would be about 22 feet wide (6.7 metre) and a single track about 14 feet (4.25 metres). The double track consisted of the main way for loaded waggons. The other track was called the bye way and was used to take the empty waggon back to the colliery. On single track ways, passing places would be constructed for the empty waggons. The ways were fenced off and constructed with a ditch at either side of the rails. The rails were made of beech wood about 4 or 5 inches square and were pinned onto wooden sleepers made of oak. The sleepers rested on a thin layer of ballast to aid drainage. The main purpose of the sleepers was to maintain the correct gauge of the rails, rather than to transfer the weight from the rails to the ballast. The ballast between the layers was piled up to the top of the sleepers or perhaps higher to form a path for the horse. Outside the rails it was piled up to the height of the rails and extended to form a path for the waggon men. The ballast would then fall to allow water to percolate into the drainage ditches.

Wooden rails were not ideal: they wore badly and created a lot of friction. A second rail would often be pinned onto the lower rail but these would often have to be replaced after a year or so. It became the practice to pin thin plates of wrought iron on the surface of the rails on curves and gradients. These reduced the friction and reduced wear on the rails, but they constantly worked loose and were expensive to maintain.

On curves there was a tendency for the flange on the outer wheel to rise onto the rail and thus derail the waggon. To prevent this a second rail would be constructed parallel to the inner rail to engage against the back of the flange on the inner wheel thus preventing the outer wheel rising.There was a switch rail at each end of the byeway and at passing points on single track ways. There is no record of the design. There were turn rails at the staiths to enable waggons to be turned through a right angle in a very confined space.

There was no standard gauge applicable to all ways, but on Tyneside it was invariably between 4 and 5 feet. If the gauge had been narrower the load would have been uneconomical; any wider it would have been too heavy for one horse to pull.

During the 17th and 18th centuries the permitted output of coal from a colliery and the amounts allowed to be carried on waggonways was measured by volume rather than weight. The three units of volume were the boll, the waggon and the ten. The capacity of a waggon was measured in bolls and the ten was defined by reference to a number of waggons. The boll was originally the tub used for loading a keel and throughout this period the weight of coal in a boll was approximately 2.2 cwt (c112 kg). Over the years the capacity and size of the waggons increased. We know this because virtually all leases and wayleave agreements defined the rent by reference to the ten and further defined the number of bolls to the waggon and the number of waggons to the ten. Thus a wayleave for the Northbanks way in 1698 set an annual rent of £630 plus 14 shillings (70p) per ten for the first 900 ten and 14 shillings (70p) per ten above 900. The size of a waggon was set at 15 bolls to a waggon and the ten was defined as 22 waggons. In modern parlance that would be a rent of £1260 per annum for the first 33,165 tonnes carried that year and a further payment of 70p for each further 36.85 tonnes carried.

Between 1700 and 1750 the size of waggons increased to between 19 and 20 bolls and from 1750 they further increased in some cases to 24 bolls.

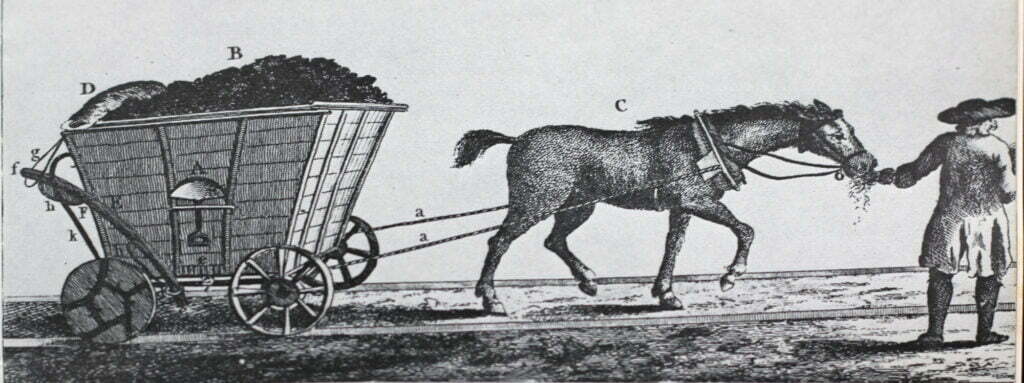

A picture of the Tyneside wagon was published in the General Magazine in 1764 with a description. It describes the waggon loaded with coal drawn by a single horse. The waggon-man is enticing the horse forward with hay in his hand. The hay is kept in a hay poke at the rear of the waggon. The top of the fore part of the waggon projects further out than the bottom. The greatest part of the loading is on the fore wheels which are considerably larger then the hind.

The brake is known as the convoy. It is used to regulate the motion of the waggon down the sides of hills (called by the waggon men, runs). The waggon man takes the end of the convoy out of the loop and lets it down onto the wheel and placing himself astride the end he presses more or less according to the declivity of the run.

When the waggon arrives at the staiths he lets down his bottom board which has hinges on one side and a hasp on the other. The coals run down an opening in the waggon way under the waggon.

By modern standards the 17th and 18th century waggonways could be extremely dangerous, particularly in wet weather. We know of the existence of the first Tyneside waggonway (the Whickham Grand Lease Way) from burial records of the parish of Whickham kept at the Durham Record Office. There is a record of two children slain at the Waggon gate on 22 October 1645 and two others slain by waggons in 1650.

The runs were particularly dangerous. It was the practice of the waggon men to unhitch the horse at the head of a downhill slope and put it behind. The greatest danger came with the rain and frost when boys and men were engaged to put ashes and cinders to roughen the rails. In really bad weather traffic had to be suspended. The General Magazine reported on the practice of fastening the horses behind the waggon on the runs, “as they would inevitably be killed were the convoy to break (which frequently happens) or any other accident occasion their waggons to run amain; nor is this fatal consequence attendant only on the horses, but the drivers often receive broken bones, bruises and frequently the most excruciating deaths.”

Pressing on a convoy also carried the risk of fire destroying the convoy or on some occasions the whole of the waggon.

While the traffic on many of the waggonways was not all that great, some were exceptionally busy. For example the Tanfield Way which opened in 1725 carried on average 930 waggons per day and a bystander would see a waggon pass at intervals of less than a minute. A catastrophic accident would therefore cause a significant hold up to the traffic.

The waggonways were private railways. They were not built under the authority of an Act of Parliament and the coal owners had no statutory powers to construct them over other people’s land. They had to negotiate rights known as wayleaves and the payments they had to make added very substantially to the cost of coal production. Land owners became very savvy and had the upper hand in negotiations, because no matter how much coal could be won from a mine, it was of no avail to the coal owner unless she or he could get it to its market. During the ‘War of the Waggonways’ in the first two decades of the eighteenth century, when cartels of coal producers were attempting to restrict the amount of coal reaching the market, the major weapon at their disposal was the closure of competitors’ waggonways. This could be done by acquiring the land over which the waggonway passed or by offering landowners a payment, known as a dead rent, conditional on the landowner revoking the wayleave. The early 18th century cartels were led by the Liddells of Ravensworth, aided by their secretary William Cotesworth. The first cartel was known as the Coal Office. Their campaign to close the Western Ways I and II can be followed by selecting these waggonways on the interactive map. The campaign came to a successful conclusion when an enlarged cartel, known as the Grand Alliance, including the Wortley/Montagues and the Bowes was formed. The Grand Allies built their own Waggonway, the Tanfield and allowed those in their alliance to connect into it. The closure of Western Ways I and II meant that the western allies (the Claverings, Ridley, Mallabar & Windsor) had no rail link for their collieries along the upper western bank of the Derwent Valley stretching from Burnopfield, Lintz (known as Bucksnook), Dipton and Pontop. Two years later, the rail link was restored when the western alliance built Western Way III between Burnopfield and Rowlands Gill and along the western bank of the Derwent to staiths at Derwenthaugh. Coal owners eventually realised that there was sufficient demand for all the coal they could produce and the war came to an end.

Maps of Waggonways in the Land of Oak & Iron

We have two maps. One is a static map which shows certain, probable and possible routes of waggonways.

The second map is an interactive map. The user can select waggonways by reference to four time slices by clicking on the appropriate stars on the legend. Alternatively all of the waggonways can be toggled on and off by selecting the Waggonways header on the legend.

You will find that there is a star next to most of the waggonways. If you click on that a pop up box will appear with the name of the waggonway. Clicking on the pop up box will take you to a web page giving more information. In each case there is a link to the Tyne and Wear Historic Environment Record for that waggonway. The interactive map also features the nineteenth and twentieth century collieries and mineral railways which can be toggled on and off by clicking on the appropriate heading on the legend. Links, providing more information will be provided in due course.

F11 toggles the full screen on and off. When in fullscreen mode, open tabs can be accessed by pointing the cursor to the top of the screen.